Mixing Art and Technology: North America’s Largest Membrane-filtration Sewage Plant Opens Near Seattle

The $1.8 billion Brightwater facility, 10 miles northeast of Seattle, eschews old notions of what a sewage plant is. State-of-the-art membrane technology produces reusable water, a trail system allows outdoor recreation, and wetlands give salmon a place to spawn.

By Brett Walton

Circle of Blue

SEATTLE, Washington — Driving on Washington’s State Route 9, which runs parallel to the new Brightwater sewage-treatment facility, a visitor would be forgiven if he imagined himself entering a county park or a sculpture garden. From the road, a passenger catches only half-views of the plant, positioned among the sapling-speckled berms, wetlands, and public art on the 46-hectare (114-acre) campus.

For some sewage-treatment facilities — even those that are not immediately visible — a person need only follow his or her nose to it. But that is not the case with Brightwater, which has $US 65 million in odor-control technology. The smelly sections of the facility are sealed, and the air is scrubbed before being released.

“The technology is to the point where we can be a good neighbor,” said Gunnar Sreibers, the project manager for construction, as he led a tour during the plant’s grand-opening celebration on September 24. After a ceremonial “first flush” and a blessing of the waters by members of the Tulalip and Suquamish Indian tribes, thousands of people took facility tours, viewed the art, walked the five kilometers (three miles) of nature trails, and learned about the treatment process.

Decades ago, sewage-treatment plants were plunked down without consulting neighboring communities — usually where minorities or the poor lived. But, in both its design and engineering, Brightwater, the largest membrane wastewater treatment plant in North America, is one of many facilities at the dawn of a new era for sewage treatment, one in which water is reused and the facility is no longer a local blight.

A New Day

“I could spend hours talking about water,” James Goetz told Circle of Blue just a few days earlier over lunch in Seattle’s Wallingford district. Goetz was the lead engineer who chose the site for the $US 1.8 billion facility, and he was also the assistant project manager for the plant’s design. The modern era of wastewater treatment in the United States began in 1972 with the passage of the landmark Clean Water Act. Goetz has seen both sides, since his career as a wastewater engineer began two years prior, in 1970, with CH2M Hill, now one of the world’s top engineering firms.

“When I started out,” Goetz said, “wastewater-treatment plants were moving from primary treatment to secondary treatment, because of water quality standards set by the Clean Water Act.” Primary treatment removes the solids, while secondary treatment uses microorganisms to eat up organic matter, in effect, accelerating the degradation that would occur naturally.

“Brightwater is an impressive facility that integrates public space and the landscape,” he continued. “It’s a work of art, really.”

Artistic Expression

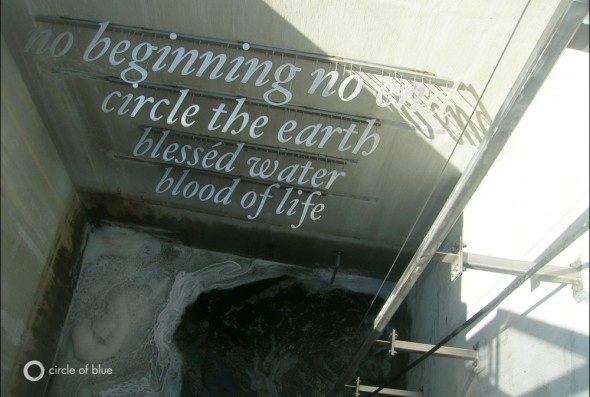

And there are plenty of pieces of work on display, as well. The 13 pieces of public art — from sculptures to glasswork — that have been placed throughout the site are not just tacked on for glitz. Because so much of the treatment process is hidden — covered behind pipes and tubes — the art is part of Brightwater’s educational mission, according to Annie Kolb-Nelson, the media spokesperson for King County’s wastewater-treatment division, which owns and operates the new facility.

The most visible piece of art is a segmented purple pipe that runs the length of the site’s entrance road and drips water on ornamental grasses below. The color purple was chosen because it conveys reusable wastewater. Other works highlight the science and infrastructure that undergird the treatment system.

Three of the artists have been part of the design team since planning began in 1999.

“I have to keep pinching myself to remember that the experience was real,” said Jann Rosen-Queralt, who worked with the architects and engineers. Rosen-Queralt — who lives in Baltimore, Maryland, and commuted periodically to Seattle for seven years — said the collaborative design process was unlike anything in her professional experience.

“The smiles you see today are not smoke and mirrors,” she said. Indeed, it was difficult to find anyone who had worked on the project who did not want to explain how marvelous it was.

Clean Water, At A Cost

Despite the evident bonhomie at the grand opening, Brightwater does have an uglier side; and the root cause is money.

The construction cost of the project increased slightly — just over 3 percent — from the baseline estimate. However, one of the machines boring a 21-kilometer (13-mile) conveyance tunnel got stuck, which delayed the tunnel’s completion by a year, while a new contractor was brought aboard. Additionally, a contract dispute with another tunnel contractor is currently being settled in court.

Though the construction cost has been finalized, how to pay for it is still being argued.

Brightwater — part of a regional wastewater system operated by King County, which is home to Seattle — was built to accommodate growth. When the construction plan was drawn up, officials from the three-county service area agreed that “growth pays for growth” and that new customers would foot most of the bill through “connection charges” to plug into the system.

But Seattle’s City Council contends that the county is not charging enough and that city customers are paying more than they should, according to the Seattle Times.

In the end, say those involved with the plant, the costs will be worth it. Sreibers, the construction manager, said that the public wanted the best available technology so that the plant would not have to be retrofitted to meet stricter water-quality regulations.

The membrane-filtration system — most commonly used to purify drinking water — produces water that can be used for irrigation and industrial processes. The water is 70 percent cleaner than conventional secondary treatment, and the facilities take up 40 percent less space. King County already has a supply contract with a golf course for a portion of this treated water. These opportunities for water reclamation, explained spokesperson Kolb-Nelson, mean that more water can be kept in rivers for fish and that agriculture in the area can be more sustainable.

“We think this is an example of how a wastewater plant can be an amenity, an asset for the community,” she said.

Goetz, the lead engineer, is excited by the final product, what he sees as the “next step” for wastewater systems in the United States. Officially, he retired from CH2M Hill in 2007, but Goetz stayed on the project to see it through to completion. Now, he’s enjoying his leisure from the houseboat he has lived on for 30 years.

“I get to enjoy the water from my home, and I got to make it a little cleaner during my career,” he said. “I think that’s perfect.”

Brett Walton is a Seattle-based reporter for Circle of Blue. Contact Brett Walton

Brett writes about agriculture, energy, infrastructure, and the politics and economics of water in the United States. He also writes the Federal Water Tap, Circle of Blue’s weekly digest of U.S. government water news. He is the winner of two Society of Environmental Journalists reporting awards, one of the top honors in American environmental journalism: first place for explanatory reporting for a series on septic system pollution in the United States(2016) and third place for beat reporting in a small market (2014). He received the Sierra Club’s Distinguished Service Award in 2018. Brett lives in Seattle, where he hikes the mountains and bakes pies. Contact Brett Walton

“Decades ago, sewage-treatment plants were plunked down without consulting neighboring communities — usually where minorities or the poor lived.” My comment is really? This seems like an awfully broad condemning statement without any facts to back this up. My experience has been entities sited treatment plants as far out of town as possible. Property values no doubt went down and often lower level housing or factories built up around the plants using the cheaper land as the cities or towns grew out toward the plant. So do you have examples where treatment plants were plunked down in the middle of existing poor neighborhoods? Hyperion in LA…mmm no that is Santa Monica. Orange County plant..mmm pretty nice neighborhood .. San Diego Point Loma? All the plants in the Las Vegas Valley? Built in the middle of the desert until the valley grew out and zoners allowed mobile home parks right up to the fences.. Also NLV just completed a 25 mgd membrane plant including an interceptor for about $280 million. Your article should explain more about what $1.2 billion dollars bought besides art. That is expensive art.

Saying that usually happens is too strong a statement. Demographics are sometimes a factor, but topography, existing infrastructure other local political concerns are generally more salient. However, several high-profile cases from the 1960s and 1970s do come to mind: Bayview-Hunters Point in San Francisco and the North River plant in New York City.

The art program cost $4 million.