West Virginia Chemical Spill Reflects Dramatic Weakness in U.S. Resolve to Enforce Drinking Water Safety

Poisoned water shut down state capital and exposed endemic carelessness in oversight.

By Codi Kozacek

Circle of Blue

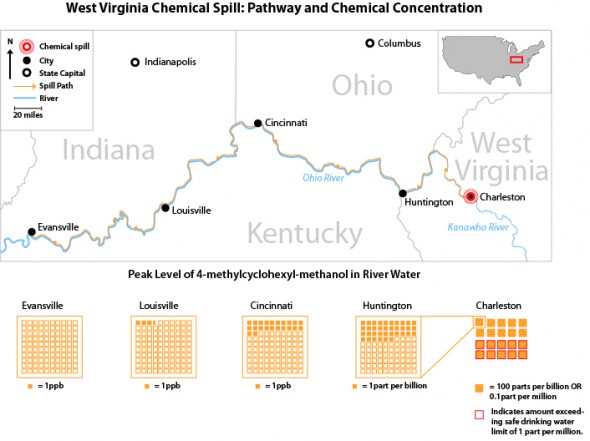

On January 9, a chemical storage tank on the bank of West Virginia’s Elk River leaked approximately 10,000 gallons of 4-methyl-cyclohexane-methanol (MCHM), a chemical used to process coal, into the river just 1.5 miles upstream of the drinking water intake for 300,000 people in Charleston, the state capital.

For five days, residents were warned not to use their tap water for any purpose—no drinking, no showering, not for washing dishes or brushing teeth.

Nearly two months later, following a chorale of mixed messages about safety, many Charleston residents are still afraid to drink from their taps.

The spill elevated to public attention a pattern of disregard, weak oversight, even neglect by West Virginia and federal regulators charged by law to oversee storage of toxic chemicals, and to safeguard the environment and public health. A Circle of Blue investigation found that not only was a harmful chemical stored haphazardly near a major drinking water source, scant information was available to regulators, public health officials, and citizens about the chemical’s effects on people and aquatic species.

Circle of Blue’s investigation also found:

- Federal and state laws and regulations to protect drinking water sources rely on voluntary measures, with no way to force implementation of protection plans.

- Funding for regulatory agencies and safe drinking water programs has declined dramatically since the early 2000s, leaving almost no money to implement the voluntary protection measures.

- Provisions of the federal Clean Water Act meant to prevent spills of hazardous materials have not been implemented.

- How chemicals and other harmful substances are classified under the law often determines how strictly they are regulated. Thorough assessments of their effects on public health and the environment are rarely completed.

“It’s an ongoing crisis, it’s not over,” Maya Nye, spokesperson for the Kanawha Valley-based People Concerned About Chemical Safety, told Circle of Blue. “People still aren’t drinking the water because we’re afraid of it. We keep getting new information about what’s in it.”

For all intents and purposes, the West Virginia spill had its start when citizens complained to the state Department of Environmental Protection about a strong licorice odor on the river. The company that owned the storage facility, Freedom Industries Inc., did not report the incident.

The local water utility, West Virginia American Water, issued a “do not use” order at 9 o’clock that evening. Local and state officials reached out to the federal Centers for Disease Control for guidance on how much of the chemical could safely be allowed in the drinking water. The CDC, initially able to find just one study about the toxicity of MCHM that was performed on rats, advised a limit of 1 part per million (ppm). Two days after West Virginia American Water began lifting the do not use orders, the CDC came back with another advisory: due to a lack of information about the health effects of MCHM, pregnant women may want to avoid the water until no trace of the chemical was found. The agency later clarified that this was precautionary, and that pregnant women are regularly advised not to consume products that are safe for others. West Virginia Governor Earl Ray Tomblin told residents “It’s your decision” whether or not to use the water. Disclosures that other chemicals were present in the leaky tank created further confusion and distrust nearly three weeks after the initial spill.

In West Virginia, these factors came together to create a public health emergency that shut down the state capital for days, cost the state millions of dollars in lost economic activity, and, most significantly, eroded public trust in the government’s ability to ensure the safety of drinking water . Three weeks after the West Virginia spill, tens of millions of gallons of coal ash and water were spilled from a Duke Energy plant into the Dan River in North Carolina. Drinking water had to be treated downstream in Virginia, and the massive coal ash leak’s effect on aquatic life is not yet known, revealing similar oversight problems, according to a report from The New York Times.

That accident, too, was accompanied by a folly of miscommunication, confusion, and regulatory neglect, according to early assessments by the state Environmental Review Commission.

Both pollution events have implications beyond West Virginia and North Carolina. They appear to be symptomatic of the nation’s diminishing capacity, after decades of political attack, to enforce environmental and public safety statutes. In the duel between Democrats seeking to expand the reach of state and federal environmental and community safety agencies, and Republicans seeking to shrink government and regulatory oversight, the GOP is clearly winning.

At $US 8.2 billion in fiscal 2014, the EPA budget is $US 200 million less in real dollars than it was in 2004, and 26.5 percent less in inflation-adjusted dollars, according to federal budget documents. The agency’s staff, which numbered 18,000 full-time employees in 2001, now numbers 16,870, according to the budget documents. Similar reductions have occurred in the budgets of state community health and environmental agencies during the same period, according to state budget reports.

The toll of such weakened resolve to safeguard the environment and health is now apparent across the country.

Agricultural pesticides and toxic waste dumps are contaminating drinking water sources in rural California communities, a trend that started decades ago and has not been addressed. In Lake Erie, phosphorus pollution from agriculture and industry has led to toxic algal blooms that shut down a public water supply for the first time ever last fall.

“We talk a lot about putting drinking water first, and what we mean by that is if you were to make drinking water protection a primary consideration up stream—when considering how we grow food, how we supply communities, how we get energy—you might make better decisions on that upstream end,” Lynn Thorp, the national campaigns director for the Washington, D.C.-based Clean Water Action, told Circle of Blue. “You might not be relying on public water systems and state water regulators so much. Instead, we turn a blind eye and let the water system treat it.”

Drinking Water Source Protections Voluntary, not Mandatory

The location of the West Virginia chemical spill—just 1.5 miles upstream of the drinking water intake for American Water’s Kanawha Valley system—was key in the scale of the disaster. State and local officials should have been aware of the facility’s potential to contaminate the drinking water source due to source water assessments that were mandated by 1996 amendments to the federal Safe Drinking Water Act. The amendments directed states to map watersheds that supply drinking water, identify potential contamination threats near drinking water intakes, and provide this information to water utilities and the public. They do not mandate any further action, though the EPA suggests measures such as creating protection plans or “prohibiting or restricting land uses that may release contaminants in critical source water protection areas.”

The West Virginia Bureau of Public Health hired contractors to conduct the required assessments between 2001 and 2003, but many have not been updated since then. The latest assessment for the Kanawha Valley system was completed in 2002, and the publicly available report does not list specific contamination sources.

More detailed assessments are available to public water utilities if they request more information, Bill Toomey, the program manager for WVBPH’s Source Water Assessment and Wellhead Protection Program, told Circle of Blue. Still, the Kanawha Valley assessment should have identified the chemical storage facility as a potential contamination source because it held a stormwater discharge permit, which would have shown up during the BPH’s database search of state-permitted facilities within a “zone of critical concern” upstream of the drinking water intake. But it is easy for this information to stop at the assessment.

“The reports, or phase one assessments, are sent to the water supply utilities,” Toomey said. “In addition to that we post a copy of the report online. There are no federal or state requirements for the water system to go beyond that or develop any sort of protection plan. It’s voluntary.”

He added that, based on questionnaires sent out by WVBPH, approximately 220 water systems in the state have created some sort of protection plan.

“Mind you, we’ve got about 1,000 water systems in the state, and we’ve got about 281 that we would refer to as community supplies—those would be water systems that serve water year-round to at least 25 customers or 15 service connections,” he said.

Again, the problem is keeping the plans updated, implementing the plans, and finding the funding to do both. West Virginia’s initial assessments were completed with help from one-time EPA funding meant to help states meet the new requirements outlined by the 1996 SDWA amendments. States were allowed to take 10 percent of their allotment under the Drinking Water State Revolving Fund to conduct the assessments.

Since then federal funding has not specifically targeted source water protection plans. The Drinking Water State Revolving Fund has seen its overall funding drop in the last few years from $US 919 million in 2012 to a requested $US 817 million for fiscal year 2014—the lowest amount ever in inflation-adjusted dollars since the program’s inception in 1997. Of that, West Virginia would receive 1 percent, or approximately $US 8 million from the DWSRF.

“Many utilities and the state agencies they work with did some sort of top-level planning activities. But I don’t know of any state where there was a program that was statewide for actual [protection] plans,” Thorp said. “It’s safe to say that some of the larger public water systems went ahead and did do ongoing reviews of source water assessments, and also planning for various kinds of contingencies. But the reason we worked so hard in 1996 for more robust source water protections—not just planning, but for some provisions to go after risks—was because absent that requirement, it is hard for public water systems to obtain funding for that kind of work, and it is hard for the state to do that work too.”

Definitions Play Major Role in Regulatory Gap

Other pieces of federal legislation, including the Clean Water Act, could have helped prevent the spill if properly implemented. The CWA’s pollution prevention program—which requires polluters to obtain permits and report discharges—does not cover facilities that don’t make regular discharges of waste material, explained Jon Devine, a senior attorney for the Natural Resources Defense Council. So while a chemical manufacturing facility would require a permit, a chemical storage tank does not.

The Act does, however, allow for regulations that require storage tanks to take spill prevention measures. But the only storage tanks that are currently covered by the Clean Water Act are those that contain oil products. The Act calls for similar regulation of tanks that hold hazardous substances, but rules to implement this measure have not been made in the 42 years since the law was passed.

“The Act has a directive for the federal government to develop a program to help prevent discharges of oil and hazardous substances,” Devine told Circle of Blue. “Under that authority, the EPA has a set of safeguards that require, among other things, the development of spill prevention and countermeasures and response plans for oil, but not for hazardous substances. It seems to us that addressing hazardous substances with a similar program is both called for by the Act and good policy.”

He added that the Act, as currently implemented, might allow for some enforcement action to be taken retroactively, but it did not have the reach to regulate the Freedom Industries facility proactively.

“Before and after are two different questions,” he said. “The company may well be liable for discharging a pollutant into the Elk River without a permit to do so. That would be a violation of the Clean Water Act. But EPA has not developed the spill prevention program under the law that I think could have helped guard against a spill in the first place. I think if the law is fully enforced and implemented, it is a strong tool, or can be a strong tool, against a host of pollution sources, including sites like the one in West Virginia that led to this spill.”

But even if such a program was implemented, Devine said, the material being stored in a tank would have to be considered hazardous under federal law before the tank would be subject to regulation.

MCHM is not considered to be a hazardous substance. Though some materials and chemicals are inherently more dangerous to humans than others, there is no real scientific difference between a chemical that is “hazardous” and one that is merely considered “toxic”. Those distinctions are largely created for political reference, according to Steven Gilbert, director of the Seattle-based Institute for Neurotoxicology and Neurological Disorders (INND).

“Hazardous and toxic are basically the same thing,” Gilbert told Circle of Blue. “If you start splitting hairs –hazard is a measure of the toxicity and the risk of exposure. If you’re not exposed, you’re not going to see negative health effects.”

But the distinction matters when it comes to regulation. The chemical storage site responsible for the West Virginia spill, operated by Freedom Industries, is a prime example. The site escaped regulatory inspections for years. This was largely because of the material being stored in the tanks and the provisions of the nations various toxic and hazardous waste storage and disposal laws.

“Prior to Freedom Industries taking over the site in the early 2000s, the facility was owned by Pennzoil and stored petroleum products (Freedom did not store petroleum products),” Tom Aluise, press officer for the West Virginia Department of Environmental Protection, wrote to Circle of Blue in an e- mail. “Because petroleum products were stored at the facility under Pennzoil ownership, there were periodic inspections by the state’s Division of Water and Waste Management up through 2002, prior to when Freedom bought the tanks. Those inspections were related to hazardous waste activities (i.e. petroleum products being stored there) at the site.”

To complicate matters, the term “hazardous” can be applied to the same material differently depending on the law.

“Crude MCHM does not appear on the CERCLA 101(14) list of ‘hazardous substances’,” Aluise wrote. “When disposed of, Crude MCHM is not a ‘RCRA hazardous waste’. Crude MCHM is a ‘hazardous chemical’ in EPCRA reporting. The term ‘hazardous’ is used in several different regulatory formats and tends to have a distinct meaning in each.”

CERCLA, the Comprehensive Environmental Response, Compensation, and Liability Act, enacted in 1980, primarily governs the release of hazardous waste from old industrial sites. RCRA, the Resource Conservation and Recovery Act, enacted in 1976, regulates how hazardous wastes are disposed. EPCRA, the Emergency Planning and Community Right-To-Know Act, enacted in 1986, requires companies to provide information about the location and quantity of certain hazardous materials to federal, state and local officials.

Asked why drinking water supplies needed to be shut down in West Virginia even though MCHM is not considered hazardous on a number of federal lists—including the Toxics Inventory and the Toxic Release Inventory—EPA responded:

“The decision to shut down the drinking water system was made by the state of West Virginia. EPA believes it is important to minimize exposure to any chemical that is accidentally introduced into a drinking water source to protect public health, especially when there is limited information regarding the chemical.”

A ‘Broken’ Chemical Assessment Process

The lack of chemical safety information has its roots in the federal Toxic Substances Control Act (TSCA). TSCA, enacted in 1976, gives the EPA the authority to assess, approve, and regulate commercial chemicals, of which there are 83,000 currently used in the U.S. There have long been problems with the law. To start, approximately 62,000 existing chemicals, including MCHM, were grandfathered into TSCA when it was passed in 1976, meaning there is scant formal scientific data available about their effects on human health. The law has not been updated since.

“TSCA provides EPA with very limited ability to require testing on existing chemicals to determine if they are safe,” the agency said in an e-mail to Circle of Blue. “EPA continues to support much needed legislative reform to ensure that the Agency has updated authority to more effectively assess and regulate potentially harmful chemicals.”

Safety information is therefore scarce for many existing chemicals. In the case of MCHM, the CDC could initially find just one toxicity study, in which rats were given daily oral doses of MCHM for 28 days. It was this study on which the CDC based the 1ppm drinking water limit, after accounting for uncertainty.

Later, six other studies were found, but they primarily addressed acute toxicity—the harm caused by a short-term exposure to the chemical. This included studies of the consequences of skin exposure and eye exposure. However, none of the studies addressed reproductive, developmental or chronic toxicity, which would have provided information about the chemical’s safety for pregnant women and children, as well as potential long-term exposure effects. All of the studies were conducted by a lab contracted by the chemical manufacturing company, a standard practice in chemical toxicity testing.

Yet safety information gaps exist even for chemicals introduced following the implementation of TSCA. Safety data is still primarily furnished by the manufacturing company, which is required to submit all available toxicity data to the EPA in a Pre-manufacture Notice (PMN). Companies are not, however, required to submit a standard set of toxicity tests. The EPA has 90 days to review each notice and make a regulatory decision about the new chemical.

“EPA utilizes an integrated approach that draws on knowledge and experience across scientific and organizational lines to identify and evaluate concerns regarding health and environmental effects, exposure and release, and economic impacts,” the agency wrote to Circle of Blue. “Because many PMNs include little or no toxicity or fate data, the program uses several risk screening approaches to facilitate assessment in the absence of specific data. This enables the evaluation of potential risks and making risk-management decisions for the new chemicals within the 90-day time frame prescribed by TSCA.”

If the EPA determines that a chemical poses an “unreasonable risk” to human health and the environment, it can require companies to provide more safety data, or it can regulate how the chemical is produced and used. According to the EPA’s website, 90 percent of new chemical notices are approved without any regulatory action taken. During the 2013 fiscal year, the agency received more than 1,000 notices for new chemicals, and had a New Chemicals Program budget of more than $US 13 million.

INND’s Gilbert called the TSCA “broken” and said the current regulatory framework puts the burden of proof on the wrong parties.

“Industry should have the requirement to demonstrate safety, but right now it’s flipped where the government and us, the people, have to demonstrate harm,” Gilbert told Circle of Blue.

He added that other federal programs, like those that assess and regulate pesticides and drugs, require much more thorough toxicology information.

“We need to require industry to put together a minimum test battery,” he said. “We need to know what is the estimated production volume, and the highest possible production volume—do [the chemicals] persist in the environment, do they bioaccumulate in tissues or organs—just a whole battery of tests, much like they do with pesticides and drugs. We know how to put it together, but it’s not being done.”

Tests like this, and their availability to emergency responders and the public, are extremely important for preventing disasters like the West Virginia spill, according to Maya Nye of the People Concerned About Chemical Safety.

“I’d like to see that every chemical that is out on the market or is going to be out on the market, is going to be tested on something else besides my community to determine its safety,” she said. “I don’t want it tested on any community.”

Evan Hansen, the president of Downstream Strategies, an environmental consulting company in Morgantown, W.Va., is hopeful that the chemical spill has focused enough attention to spur action.

“I do think that the underlying, most fundamental issue in protecting the environment and public health is having a state government that takes the responsibility seriously and understands the link between clean water and economic development,” Hansen told Circle of Blue. “Many legislative leaders are making it very clear in public statements that they understand the link between water and economic development, that providing clean water to the people of West Virginia is their most important concern, and that it’s a false choice to even think of choosing between water and economic development. Many leaders in the state legislature have changed their tone.”

A news correspondent for Circle of Blue based out of Hawaii. She writes The Stream, Circle of Blue’s daily digest of international water news trends. Her interests include food security, ecology and the Great Lakes.

Contact Codi Kozacek

There is another layer to the regulatory mix which is the RCRA which stands for Resource Conservation Recovery Act. That is designed to ensure that no hazardous waste makes it into the environment. The critical realization is that the instant a substance gets out of its package, it becomes waste and is subject to this law. This is where Freedom Industries really messed up. Since all tanks, pipes, pumps, conveyors, whatever, eventually leak or spill, the requirement is to have a plan and system in place to catch or contain the spill and keeping it from getting into the environment. The requirement is to have a containment wall around tank farms to catch and contain the contents of the largest tank. The containment wall must be impermeable to the material in the tank. Employees must be trained to react to a spill. Clearly neither the containment nor employee education was adequate because the chemical flow into the river occurred for more than 24 hours.

Very nice post-mortem on the institutional weaknesses that turned the (avoidable?) spill into a disaster.