The plumes from steam-cured CIPP installations hold a soup of partially cured plastic, liquified resin, and volatile organic compounds. Photo: Obtained from Shoreline, WA government website.

Industry insists that cured-in-place plastic pipe liners are safe, but some scientists say the installation process is under-regulated and hazardous.

By Robin Lloyd – Originally published on Undark

In October 2017, Brett Morrow, a 22-year-old rugby player known as “String Bean” to his teammates, died while helping to install a plastic liner inside a Chicago-area sewer pipe. He had descended a 20-foot-deep manhole and then crawled 30 feet into the newly lined pipe, measuring two feet in diameter. At some point, the plastic liner crumpled and started to harden around him. A dangerous concentration of an ingredient in the liner, styrene, seeped out as gas and likely crippled him. Morrow drowned in liquid generated by the installation process, according to a medical examiner’s report. The drowning caused his death, but the styrene incapacitation was a “significant contributing factor,” the report stated. It took nearly four hours for firefighters to free his body.

Six months later, the Occupational Safety and Health Administration (OSHA) levied $77,604 in penalties against Benchmark Construction Company Inc., the Bartlett, Illinois-based firm contracted for the pipe work. OSHA cited Benchmark for exposing employees to airborne concentrations of styrene gas exceeding federal industrial safety standards, failure to test the air in the manhole and pipe for water and dangerous gases, and more. Benchmark contested the OSHA finding and ultimately paid $55,000 to the agency and improved its safety operations, OSHA records show.

“People make mistakes and these things happen,” said Benchmark President Mark Atkins, who only spoke with Undark, he adds, to help prevent future workplace tragedies. “There are safety guidelines in place and all of them weren’t followed, and then you have an accident, an unfortunate accident.”

Atkins would not discuss the case in detail due to an ongoing civil lawsuit brought by Richard Morrow, Brett’s father. Matthew Belcher, Richard Morrow’s attorney, says the lawsuit isn’t for financial gain, and any proceeds would be devoted to increasing awareness of the hazards associated with these chemical exposures. “It remains the goal of the Morrow family,” Belcher said, “that no one else will have to bury their son because of a similar exposure.”

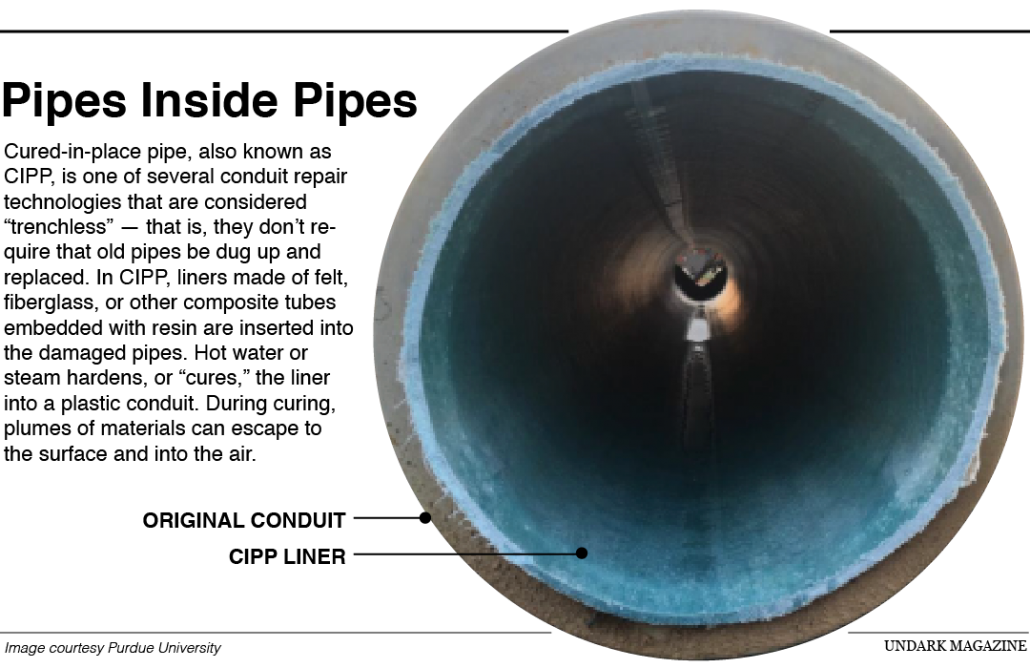

Benchmark is one small player in an industry that is virtually unknown to the public but has been fixing crumbling infrastructure in the United States for more than 40 years. The industry rehabilitates underground pipes — primarily for sewage and stormwater but increasingly for drinking water, too — using a technology called cured-in-place pipe, or CIPP. With this approach, which is one of the most popular pipe repair technologies in the country, new plastic pipes are chemically manufactured inside old damaged pipes. According to Stratview Research, a market research company, the global market for CIPP is set to reach $2.6 billion by 2023.

Members of the CIPP industry and their customers — mostly cities, counties, and sewer and water districts — routinely say the pipe-lining installations are safe. But a 2017 report from Andrew Whelton, a civil and environmental engineer, and his colleagues at Purdue University suggests otherwise. The Purdue study, primarily funded by the National Science Foundation, was the first evaluation of CIPP emissions into the air to be published in a peer-reviewed journal. The study also documented 59 incidents around the world in which residents complained about the odor at CIPP jobs or reported feeling sick after being exposed to job site emissions. Since then, the team has identified more than 40 additional such incidents.

In this demonstration video by Insituform, one of many companies providing CIPP repair technology, the company explains a typical installation process.

In 2011, for example, two day care centers, one in Worcester, Massachusetts, and one in Port Huron, Michigan, were evacuated in separate incidents when fumes from CIPP work overcame children and staffers. The same year, fumes from a CIPP installation sent five students and a high school staff member in Birmingham, Michigan, to the hospital. In September 2017, some 36 students reportedly fell sick with nausea, coughing, or headaches due to fumes from an installation at an elementary school in San Diego.

In some CIPP exposure cases, residents temporarily moved out of their homes. A family in Prairie Village, Kansas, was driven to a hotel for a night in 2014 to escape the fumes after an installation near their home. The father called the exposure experience “ghastly.” That same year, a retiree moved out of her townhouse in Baltimore for three and a half weeks to escape fumes and odors associated with a CIPP project in front of her home.

Cases like these combined with Morrow’s death and recent studies have convinced Whelton that the safety of CIPP installation work is questionable, and the Purdue team’s report has put a national spotlight on an industry that has worked for years to deflect and minimize concerns about plastic-lined pipes releasing potentially hazardous levels of chemicals into air, water, soil, and homes. “I’ve seen enough evidence to recognize that exposure to CIPP emissions can be harmful,” he said, “and something needs to be done immediately to change the practice.”

The report also inflamed an already tense relationship between members of the industry and Whelton, culminating in intimidating letters from the industry, attacks on social media, and legal threats. So far, Whelton is unfazed. “First of all, who gave you permission to pump this stuff into my private property or commercial building?” he said. “And second of all, why? Why are we allowing this to happen?”

Even without industry resistance, Whelton’s call for change won’t come easy. Updates to the nation’s sewer and water infrastructure have been sluggish for decades, in part because it is expensive and time-consuming to keep up with demand. One million miles of underground water pipes in the U.S. need to be replaced, according to a 2012 report from the American Water Works Association. The report estimated that restoring and expanding the nation’s water mains will cost at least $1 trillion through 2035. And $271 billion will be required in the next few years to do the same for the nation’s sewers and other wastewater infrastructure, according to a 2016 Environmental Protection Agency (EPA) report.

For decades, the main option for replacing old pipes was to dig long trenches to extract and replace them. Then, first in the 1970s and with more force in the 1990s, the CIPP industry offered utilities and other customers a cheaper and faster solution. Rather than extracting and replacing entire pipes, CIPP installers could access an existing pipe at manholes, and then feed in liners that would blanket the full length of a pipe interior, covering all leaks, corrosion, and other wear and tear. The industry has installed cured-in-place liners inside more than 35,000 miles of pipe worldwide, according to a 2017 BCC Research market report, which is enough to circle the globe nearly one and half times.

One reason CIPP installation is faster and cheaper is because it essentially manufactures plastic pipes outdoors. Other common plastic pipes, such as polyvinyl chloride (PVC) pipes common in household plumbing, are made in closed, internally ventilated factories where hazardous byproducts are relatively easy to capture, contain, and monitor. By contrast, most CIPP work takes place wherever the aging pipes are located. The liners start as felt, fiberglass, or other composite tubes embedded with resin. The tubes then undergo a chemical process called curing that hardens them into plastic when exposed to hot water, steam, or ultraviolet light. During curing, a plume of material can rise to the surface and stream into the air.

This raises safety questions, Whelton says, about the types of chemicals emitted and the amounts that may cause health or environmental problems. “All those questions weren’t really an issue inside of a manufacturing facility, because you would have a ventilation system that would suck up all that material,” he said. “But you don’t have that with cured-in-place pipe technology.”

The CIPP industry does have to comply with regulations from OSHA, including those designed to protect workers in confined spaces like the one where Morrow died, as well as the Clean Water Act administered by the EPA. There are also state and local regulations. But it’s unclear how effective all of these rules are given the paucity of reliable data and independent monitoring.

The plumes from steam-cured CIPP installations hold a soup of partially cured plastic, liquified resin, and volatile organic compounds, which Whelton’s team described for the first time in the 2017 study. Without respirators and gloves, workers and others nearby risk inhaling and touching these compounds. One compound is styrene, a key ingredient in most of the resins, which reportedly incapacitated Morrow at the Chicago-area installation.

According to the National Toxicology Program, styrene is “reasonably anticipated to be a carcinogen,” and the EPA classifies it as a hazardous air pollutant. Styrene exposure affects the human nervous system and can cause headaches, fatigue, hearing loss, eye and other mucous membrane irritation, concentration problems, and slowed reaction times. Workplace styrene exposure is also linked to respiratory disease.

While Whelton’s team has found other hazardous air pollutants at CIPP installations, including dibutyl phthalate and phenol, discussions of CIPP emissions often focus only on styrene. Most of the jumble of federal limits on styrene pertain to workers. OSHA regulations limit a CIPP installer’s average exposure during an 8-hour workday to under 100 parts per million (ppm), the equivalent of 100 grains of sugar in 273 sugar cubes. The agency limits exposure at any one time to 200 ppm, and spikes of styrene should never exceed 600 ppm for five minutes in any three-hour period.

According to the National Association of Sewer Service Companies (NASSCO), one of the industry’s primary trade organizations in North America with about 620 member organizations, various job sites have been monitored for styrene for decades and the industry employs its own voluntary limit of 50 ppm averaged over an 8-hour period. “I think anyone in the CIPP industry would agree that the styrene emissions on job sites are well below the industry standards for styrene emissions,” said Lynn Osborn, NASSCO’s technical director.

It’s hard to fact-check NASSCO’s claims because no federal agency seems to tally and break down emissions violations in the CIPP industry. Still, accumulating peer-reviewed research suggests that some CIPP workers are exposed to unsafe levels of styrene. And in at least one case, styrene overexposure is well documented by a government agency. Morrow’s blood had concentrations of styrene ranging from 220 to 270 ppm, according to an OSHA investigation released in April 2018 — exceeding the 200 ppm OSHA exposure ceiling. The OSHA report says Morrow was exposed to styrene for up to four hours.

Industry resistance to CIPP research that raises safety concerns stretches back more than a decade. The first studies focused on environmental contaminations, mainly of streams and freshwater life at job sites in Virginia. In the mid-2000s, an employee from the Virginia Transportation Research Council, part of the state Department of Transportation, noticed a filmy resin leaching into a stream from a plastic-lined stormwater culvert that the state had recently installed. The film prompted Bridget Donaldson, a research scientist with the council, to test the water. She collected water at several other installations over the course of a year. In some cases, she found styrene levels that would have been toxic to water fleas and rainbow trout, species that biologists use to measure water quality.

“I had absolutely no desire to do a study that showed that the people that pay my salary are buying this product that is potentially environmentally damaging,” Donaldson said. “The Virginia Department of Transportation wants to use this technology. It just wants to use it in an environmentally safe way.”

Still, Donaldson’s results were troubling. In 2007, her work led to a temporary ban on new CIPP projects at culverts maintained by the state transportation department. The following year, the department lifted the ban after setting new regulations, which required installers to capture resin debris, wastewater, and rinse water and dispose of it at wastewater treatment plants. Despite the reversal, the industry went on the defensive.

A large CIPP company, the name of which Donaldson wouldn’t share with Undark on the record, requested her data under public records laws. She complied. And during a session at a 2009 trade conference dedicated to discussing her results, Ed Kampbell, an engineer with decades of experience studying and working with CIPP, criticized her sampling methods and conclusions. In a write-up of his presentation in a trade publication, Kampbell wrote that “good housekeeping” to prevent and clean-up resin spills and complete curing will “lead to a proper cure and a long CIPP life; and in this author’s opinion, no measurable environmental impact.” But her findings withstood the test of time: Studies in three other states have since documented CIPP culvert installations with similar water pollution.

(There have also been documented cases of incidental drinking water contamination occurring during the installation of CIPP liners, but scant research addresses the safety of drinking water that is delivered through pipes that have been repaired using the CIPP process. The industries and organizations that provide drinking water and related infrastructure typically comply with regulatory standards set by NSF International, a Michigan-based, not-for-profit organization, as well as state standards set in accordance with the U.S. EPA’s limits on dozens of contaminants. However, Whelton says that there are no U.S. drinking water standards for many of the chemicals that limited research suggests could be released from CIPP water pipes.)

The conflict between research science and the cured-in-place pipe industry came to a boil in 2015 when Elena Ajdari, then a graduate student at the University of New Orleans, captured air emissions at several CIPP projects in a major U.S. city as the basis of her dissertation. Ajdari would not reveal the location to Undark to comply with a request from the city.

Ajdari hired an independent lab to analyze her samples, which found styrene levels peaking at 250, 289, and 1,070 ppm. The results alarmed Ajdari.

“I didn’t think that I would discover something very new,” said Ajdari. “But then I got the result at the end of the project, and I understood that I did something very big.”

Whelton, who had assisted with Ajdari’s study design, routinely cites her dissertation and says the research was done in Los Angeles. In late 2015, Whelton traveled to Los Angeles and met with a handful of city staffers in the Bureau of Engineering to provide more context for Ajdari’s findings, which included demonstrating her air testing equipment and explaining how she collected samples. Afterwards, Whelton alerted several other state utilities to the Los Angeles findings.

About a week later, in early December, Edward Arrington, then a senior engineer in the Los Angeles bureau, sent an email to Whelton that disavowed knowledge of the very data collection and analysis that Whelton had presented. Arrington added: “Under no circumstances should you include or infer any involvement by the city of Los Angeles in any of your presentations, discussion, correspondence, etc. regarding this matter.”

News of Whelton’s discussions about the Los Angeles findings also reached Ted DeBoda, then the executive director of NASSCO. In February 2016, DeBoda responded through a certified letter, delivered to Whelton at Purdue. The letter asked Whelton to “refrain from further meetings with owners who utilize or are considering the use of CIPP for sewer rehabilitation until we can develop a dialogue.” The letter also said that NASSCO disagreed with the findings turned up by Ajdari and requested a “constructive dialogue” between Whelton and the organization, “to ensure the public has the most reliable information.”

Whelton passed the letter to university lawyers and continued his work.

In July 2017, Whelton and his colleagues published the air emissions findings that ratcheted up the dispute with the CIPP industry. At each field site for the study, the CIPP installers used steam to harden, or cure, the resin, a common technique. The results showed the emissions weren’t just steam, as industry members typically describe them, and drew more publicity than past studies. Some customers, including the District of Columbia Water and Sewer Authority, approached contractors and NASSCO to ask if the pipe lining technique was safe.

A heated public exchange ensued. Right after the Purdue study came out, NASSCO formed a group to address the findings. Members included industry representatives from the American Composites Manufacturers Association, NSF International, and the North American Society for Trenchless Technology.

The NASSCO group reviewed the Purdue study and decided that “claims regarding the safety of steam-cured CIPP installations are premature and certainly not conclusive,” according to an October 19, 2017 recap by Osborn in the trade publication Trenchless Technology.

In August 2017, NASSCO took direct aim at the study in a press release riddled with errors, such as describing the work as a study “completed by [Whelton’s] students” “without any apparent peer review.” In fact, the paper’s 11 co-authors include six faculty and five students — four graduate students and one undergraduate at the time. And the journal in which the Purdue study was published, Environmental Science & Technology Letters, is peer-reviewed.

NASSCO did make a correct point: Whelton’s group did not run its findings past the industry group prior to publication. But scientists often publish results without consulting funding agencies or organizations in order to maintain intellectual independence. And contrary to a claim by the trade group, the research team consulted NASSCO material and other industry sources for their report, including information from a day-and-a-half long NASSCO training on pipe-lining installation, which Whelton attended in person.

The trade group’s press release also announced a plan for a rebuttal report, “an independent study and research program that will be properly peer reviewed to challenge and/or confirm the information developed and published previously.” NASSCO published its request for proposals in September 2017, listing four CIPP emissions studies that researchers must examine — the Whelton group’s 2017 study, Ajdari’s dissertation, one of Donaldson’s water quality studies, and another state transportation agency study.

Also that September, the Purdue team published online a detailed public response to the NASSCO press release, saying that it “made many incorrect assertions.” The Purdue statement estimated that in the history of CIPP installations, “thousands if not more people may have been chemically exposed at worksites, in their homes, offices, schools, and day care centers.” The team recommended that CIPP companies immediately notify all current and former clients that they can’t rule out CIPP-related health risks.

Meanwhile, some industry members spoke out on social media. For instance, Eric Sullivan, a NASSCO trainer, posted an essay on LinkedIn casting doubt on the Purdue study and disparaging Whelton and the National Environmental Health Association (NEHA), a professional organization. NEHA had hosted a webinar in which Whelton presented the study results. “It’s clear that both Whelton and NEHA have a significant lack of understanding of the most basic configurations of sewer collection systems,” Sullivan wrote. “The impact of this is that it risks misrepresenting the results of the study and grossly exaggerating the potential hazards themselves, if any, of the CIPP steam cure method.”

In December 2017, NASSCO released updated guidelines for the use and handling of styrene-based resins in plastic-lined pipe work. Recommendations included “proper personal protective equipment,” the maintenance of a perimeter around the job site to keep the public out, and “good housekeeping practices.” Regarding the 2017 Purdue findings, the update stated “no evidence was produced regarding the health effects of CIPP steam exhaust on either workers or the public.” While it’s true that the study did not measure human health effects, these were outside its scope. The Purdue study did, however, show that condensed emissions captured at two of the job sites were at levels toxic to mouse lung cells and immune cells.

The updated guidelines also stated “there have been no noted serious consequences reported” in the history of CIPP’s use of the two mostly widely used types of resin. However, Brett Morrow, whose death was attributed in part to styrene toxicity, died on the job two months before the guidelines published.

In March 2018, NASSCO announced a new executive director: Sheila Joy, who had a background in marketing, including some work with the CIPP industry. The previous executive director, Ted DeBoda, was a civil engineer and had resigned in January.

Then, on March 14, 2018, when Whelton was out of town, a letter was delivered by certified mail to his home and handed to his wife. The letter, from a lawyer for Insituform Technologies LLC, a leading CIPP company in North America accused Whelton of “environmental alarmism” and stated, in part, that “Insituform insists that you cease and desist your disparaging comments against Insituform and CIPP immediately.”

The Insituform letter also stated that Whelton, in an article he co-authored in a monthly magazine for members of the American Public Works Association, failed to acknowledge “that the most likely cause of Brett Morrow’s death was overexposure to the hydrogen sulfide gas typically found in sewer gas, and not due to overexposure to styrene and other VOC gases related to the CIPP project.” There is no mention of hydrogen sulfide in Morrow’s autopsy report of November 27, 2017.

The letter also described “the Whelton Group” as a business seeking commercial gain. The characterization could stem from a patent application the Purdue Research Foundation filed in 2017 for a system that captures, separates, and analyzes emissions from pipe-lining job sites. The application names Whelton and four of his Purdue colleagues as inventors.

Whelton counters that his team didn’t invent the system to start a business, but out of necessity. They needed a such a device to speed up their work and couldn’t find one, so they built it themselves. As of this writing, Whelton hasn’t formed a company related to the system and says he has no plans to do so. “We didn’t get into this because we wanted to patent something,” he said. “Our focus has been and continues to be science — figuring out what the materials are in and released by CIPP, how to capture them, and providing guidance to health officials so they can make decisions regarding exposures.”

Stephen Callahan, vice president of global human resources and safety for Aegion, Insituform’s parent company, says of its profit assertion that “Whelton’s claims merit further questioning.”

Again, Whelton handed the letter to university lawyers and continued his work.

But the tension persisted, says Mike Burkhard, a former executive director of NASSCO and now executive director of business and technology at Reline America, a Virginia-based company that makes fiberglass liners and installation systems for them: The whole industry, he said, was “in an uproar.”

In December 2017, as promised, NASSCO launched its self-study. The first of two phases was the review of past studies, a task NASSCO assigned to the Center for Underground Infrastructure Research and Education (CUIRE) at the University of Texas at Arlington. A primary funding source for CUIRE is industry, and the center is overseen, in part, by a board that includes an Insituform technical manager and Lynn Osborn, the NASSCO technical director. The second phase of the study launched in June 2018 to collect and analyze data from several CIPP installation sites. NASSCO announced that the Trenchless Technology Center at Louisiana Tech University would do this work in a partnership with the Army Corps of Engineers’ Engineer Research and Development Center. The Louisiana Tech center also receives significant industry funding and includes CIPP industry board members.

The literature review, completed last year, echoed the NASSCO group’s original response, raising doubts about the methodologies of the CIPP emissions studies they looked at and deeming the research results “not conclusive.” The second-phase results are expected to be released in the next few months. “NASSCO has nothing to gain by CIPP being proven safe or unsafe,” said Joy, the new executive director. “I want these studies to come out 100 percent pure, clean, impartial.”

Osborn also wants trustworthy findings. “Everyone I visit with and talk to is interested in one result and that is to get to the truth, whether it be Dr. Whelton’s side or the individual contractors who are out there doing testing,” he said. “Because obviously they want to protect their workers and the public and NASSCO.”

In the meantime, most CIPP installations are proceeding as they were. But in some small ways, Purdue’s work is already prompting changes. Following conversations with Whelton, Pleasants Construction, a Maryland-based CIPP installation company, requested a voluntary federal evaluation of potential hazards at its work sites, including styrene emissions. Researchers with the National Institute for Occupational Safety and Health (NIOSH), a branch of the Centers for Disease Control and Prevention, did the study, and the results came out in January.

As part of the study, NIOSH researchers measured styrene levels at a UV light-cured installation site, both when the ventilation fans were temporarily turned off and during regular use. With the ventilator off, one worker was exposed to 140 ppm of styrene while grinding a cured pipe — exceeding the NIOSH recommended 15-minute exposure limit. When it was on, styrene levels were below NIOSH’s safety limit of 100 ppm, averaged across a 15-minute interval.

Overall, the analysis pinpointed specific installations tasks — such as cutting and taping liners and grinding cured pipes — that can put workers at risk for exposures to styrene and other volatile organic compounds. In their report, the NIOSH researchers recommended manhole ventilation when workers are interacting with uncured or cured liners and endorsed other safety measures the company already takes, such as bagging used gloves and excess liner immediately after it is ground off.

Any company can request a NIOSH health hazards evaluation, which is free, but so far, only a handful of state agencies and companies have come forward. “We’re in the infancy of really investigating this,” said Ryan LeBouf, the research chemist and industrial hygienist at NIOSH who headed the Pleasants evaluation.

Whelton and his colleagues also are making recommendations for people at or near CIPP lining installations: No one should inhale installation fumes. Workers and others at job sites should wear face masks and gloves and avoid touching materials. Contractors should capture emitted gases, curing waters and vapors, scraps of resin, and other waste. Work sites should be monitored to ensure that fumes are being contained.

Without such measures, the Purdue team maintains that more ecosystems and people, including workers, will be harmed. And the health threats to workers, which can be fatal as was the case for Brett Morrow, particularly sadden Whelton.

“This young kid, 22 years old, healthy, succumbed to an organization that refused to acknowledge the chemical safety issues associated with their technology,” Whelton said. “And that incident happened months after the consistent and widespread attacks on the research where we raised up a hand and said, ‘There’s an issue here that you need to investigate.’”

Robin Lloyd is a freelance writer, editor, and educator, as well as a contributing editor for Scientific American and an adjunct professor at New York University’s Science, Health and Environmental Reporting Program.

This article was originally published on Undark. Read the original article.